|

UC Series

Ultra Cone Fenders

|

3rd generation UC series boast highest E/R performance under current

fender technology

3rd generation UC series boast highest E/R performance under current

fender technology

Higher energy absorption at comprable reaction force level, or reduced

reaction force at comparable energy absorption level over nearly all

other fender products at the same standoff

Higher energy absorption at comprable reaction force level, or reduced

reaction force at comparable energy absorption level over nearly all

other fender products at the same standoff

Unrivaled performance under angular compression

Unrivaled performance under angular compression

Suitable for most applications involving large vessels

Suitable for most applications involving large vessels

Work with other Zalda components such as structural PE front pad, steel

front panel with UHMW PE facing, mechanical mtion guidance device, and

various hardware to form different application system

Work with other Zalda components such as structural PE front pad, steel

front panel with UHMW PE facing, mechanical mtion guidance device, and

various hardware to form different application system

Suitable for Zalda Technology Fender Monitoring System

Suitable for Zalda Technology Fender Monitoring System

|

|

|

Performance

Information

|

|

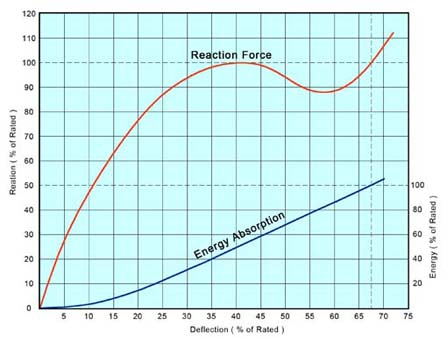

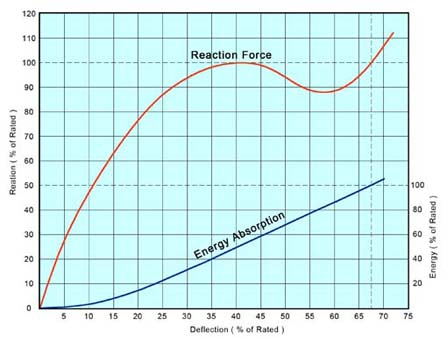

- Typical performance curves shown here represent

general ER performance of the whole series. Actual performance of

individual model may vary slightly.

- Horizontal axis represent compression rate of

original fender height / standoff. Vertical axis represent energy

absorption / reaction force percentage of rated energy absorption (E) /

reaction force (R) values. See performance data table below for

rated ER value.

- E (energy absorption) in T-m; R (reaction

force) in T; All standard performance data listed has 10% tolerance

- Maximum fender deflection @ 70-72.5% yields 5%

more energy absorption / 10% more reaction force

- Only 6 of 30+ standard formula listed here in.

Customized performance model available with special rubber formulation

and critical section structure. Contact Zalda for more details.

|

|

|

|

Model |

UC |

UC |

UC |

UC |

UC |

UC |

UC |

UC |

UC |

UC |

UC |

UC |

UC |

UC |

UC |

UC |

UC |

UC |

UC |

|

67.50% |

300 |

350 |

400 |

500 |

550 |

600 |

700 |

800 |

900 |

1000 |

1050 |

1100 |

1150 |

1200 |

1300 |

1400 |

1600 |

1800 |

2000 |

|

L9 |

E |

0.77 |

1.02 |

1.98 |

3.72 |

5.39 |

5.87 |

9.17 |

14.7 |

20.5 |

27.5 |

33.2 |

35.3 |

40.8 |

45.1 |

56.6 |

71.2 |

105 |

162 |

240 |

|

R |

5.22 |

6.58 |

8.44 |

13.1 |

17.4 |

19.2 |

26.8 |

35.3 |

44.7 |

55.2 |

63.8 |

64.6 |

70.3 |

75.3 |

88.5 |

101 |

133 |

180 |

236 |

|

S1 |

E |

0.79 |

1.14 |

2.06 |

4.16 |

5.62 |

8 |

13.2 |

19.3 |

27.7 |

37.3 |

42.5 |

49.9 |

57.2 |

63.7 |

81 |

103 |

152 |

219 |

269 |

|

R |

5.63 |

6.94 |

11.2 |

16.1 |

21.4 |

25.6 |

36.8 |

46 |

60.3 |

74.5 |

81.7 |

90.9 |

98.3 |

106 |

127 |

147 |

192 |

245 |

267 |

|

S6 |

E |

1.01 |

1.54 |

2.54 |

4.93 |

6.62 |

9.38 |

15 |

22.1 |

31.9 |

42.9 |

49 |

57.4 |

65.5 |

71.8 |

92.8 |

118 |

175 |

250 |

329 |

|

R |

7.09 |

9.37 |

13.6 |

18.9 |

24.6 |

29.2 |

41.4 |

52.1 |

68 |

84.2 |

92.4 |

103 |

111 |

120 |

143 |

165 |

217 |

277 |

315 |

|

H1 |

E |

1.24 |

1.95 |

3.04 |

5.73 |

7.66 |

10.8 |

16.9 |

25 |

36.3 |

48.8 |

55.7 |

65.1 |

74.1 |

82.3 |

105 |

134 |

200 |

284 |

393 |

|

R |

8.55 |

11.8 |

15.9 |

21.7 |

27.7 |

32.7 |

46 |

58.2 |

75.6 |

93.9 |

103 |

114 |

123 |

133 |

159 |

184 |

241 |

308 |

362 |

|

H6 |

E |

1.42 |

2.28 |

3.52 |

6.68 |

8.92 |

12.5 |

19.5 |

29 |

41.8 |

56.2 |

64 |

74.5 |

85.5 |

94.9 |

121 |

154 |

227 |

324 |

450 |

|

R |

9.68 |

13.7 |

17.9 |

25.4 |

32.3 |

37.3 |

51.6 |

65.9 |

85.3 |

106 |

116 |

129 |

139 |

151 |

179 |

206 |

272 |

347 |

414 |

|

SH1 |

E |

1.61 |

2.62 |

4.02 |

7.63 |

10.2 |

14.2 |

22.3 |

33.1 |

47.5 |

63.9 |

72.6 |

84.3 |

97.3 |

108 |

137 |

174 |

254 |

367 |

508 |

|

R |

10.8 |

15.6 |

19.8 |

29.1 |

36.8 |

41.9 |

57.2 |

73.5 |

94.9 |

118 |

130 |

143 |

155 |

168 |

199 |

229 |

302 |

386 |

466 |

|

|

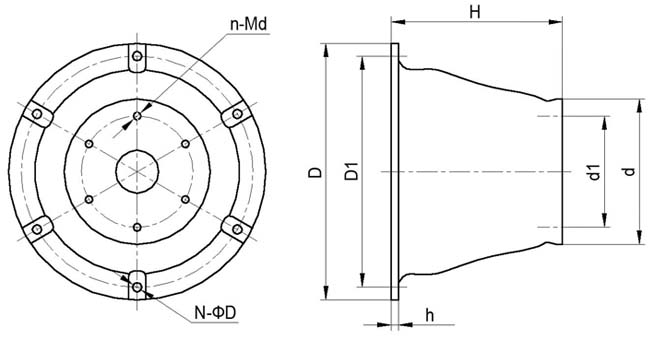

UC Series Dimension Table

|

|

|

Model |

Dimensions |

|

H |

h |

D |

D1 |

d |

d1 |

Bolt

Hole |

Bolt Size |

|

UC 300 |

300 |

15 |

450 |

405 |

255 |

195 |

4-F25 |

4-M20 |

|

UC 350 |

350 |

15 |

525 |

473 |

297 |

228 |

4-F25 |

4-M20 |

|

UC 400 |

400 |

20 |

600 |

540 |

340 |

260 |

4-F30 |

4-M24 |

|

UC 500 |

500 |

25 |

750 |

675 |

425 |

325 |

4-F30 |

4-M24 |

|

UC 550 |

550 |

25 |

825 |

743 |

467 |

358 |

4-F30 |

4-M24 |

|

UC 600 |

600 |

27 |

900 |

810 |

510 |

390 |

6-F38 |

6-M30 |

|

UC 700 |

700 |

32 |

1050 |

945 |

596 |

456 |

6-F38 |

6-M30 |

|

UC 800 |

800 |

36 |

1200 |

1080 |

680 |

520 |

6-F44 |

6-M36 |

|

UC 900 |

900 |

41 |

1350 |

1215 |

766 |

586 |

6-F44 |

6-M36 |

|

UC 1000 |

1000 |

45 |

1500 |

1350 |

850 |

650 |

6-F50 |

6-M42 |

|

UC 1050 |

1050 |

45 |

1570 |

1420 |

890 |

680 |

6-F50 |

6-M42 |

|

UC 1100 |

1100 |

45 |

1650 |

1485 |

936 |

716 |

6-F50 |

6-M42 |

|

UC 1150 |

1150 |

45 |

1725 |

1550 |

998 |

750 |

6-F50 |

6-M42 |

|

UC 1200 |

1200 |

45 |

1800 |

1620 |

1020 |

780 |

8-F55 |

8-M42 |

|

UC 1300 |

1300 |

50 |

1950 |

1754 |

1104 |

844 |

8-F60 |

6-M48 |

|

UC 1400 |

1400 |

50 |

2100 |

1888 |

1190 |

910 |

8-F60 |

8-M48 |

|

UC 1600 |

1600 |

60 |

2400 |

2158 |

1360 |

1040 |

8-F60 |

8-M48 |

|

UC 1800 |

1800 |

60 |

2700 |

2428 |

1528 |

1170 |

10-F70 |

10-M56 |

|

UC 2000 |

2000 |

90 |

3200 |

2920 |

1955 |

1710 |

10-F70 |

10-M56 |

- All dimensions in mm.

- Bolt hole positions can be customized

- Allow buckling space of D=1.8H in system design

- Allow top bracket standoff 0.15H in

system design

|

|